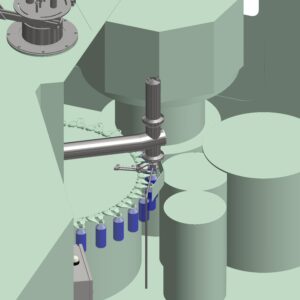

LN2 is supplied to the doser by a vacuum insulated pipe and flows into the dosing head. Sensor will detect the container and send pulses to the controller. Controller will command the dosing head to dispense the required amount of LN2 into the container. LN2 droplets quickly evaporate and expand 700 X into gaseous N2 equivalent, filling the container headspace with inert N2 gas at the desired pressure.

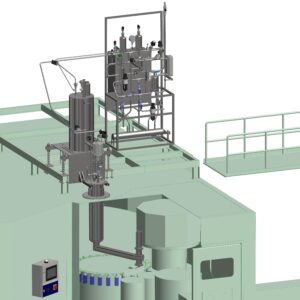

Introducing a pristine, low-pressure liquid nitrogen doser designed for swift and effective sterilization. Choose from two sterilization methods: moisture-rich steam or high-temperature dry heat to meet your specific needs. This doser features a frost-free design and is crafted from 316L pharmaceutical-grade stainless steel for unparalleled purity and durability. Outfitted with either a single or dual 0.2-micron gas filters, it delivers precise nitrogen dosing, seamlessly integrating into aseptic filling lines capable of accommodating anything from modest to high-volume production speeds.

• Sterile and Low-Pressure Dosing: The Aseptic NovoDoser offers aseptic and low-pressure liquid nitrogen dosing, making it ideal for a variety of industries, including pharmaceuticals, biotechnology, and food processing.

• Continuous Stream Dosing: Designed to run in a continuous dose mode, the Aseptic NovoDoser provides a constant stream of liquid nitrogen for uninterrupted dosing operations, ensuring optimal efficiency.

• Precise Dosage Control: With an accuracy of ± 3% in dose weight, the system ensures consistent and precise dosing, reducing waste and improving overall product quality.

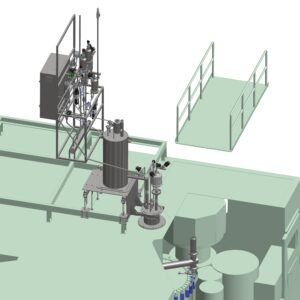

• Self-Monitoring and Alarm Outputs: The system features continuous self-monitoring, providing real-time data to operators and alerting them in case of any deviations or irregularities through alarm outputs and visual beacon indicators.

• User-Friendly PLC Platform: CSM Aseptic NovoDoser is equipped with a Siemens S7-1200 PLC platform, offering intuitive and efficient control over the dosing process, ensuring ease of operation and quick setup.

• User Interface: The system is complemented with a Siemens 6″ color touchscreen, providing operators with a user-friendly and informative interface for convenient control and monitoring.

• Automatic CIP Protection: The Aseptic NovoDoser is equipped with CIP (Clean in Place) process. This feature prevents moisture from entering the dosing head, minimizing the risk of freeze-ups and ensuring a smooth and hassle-free cleaning process. The nozzle is designed to withstand high-pressure washdowns and aggressive chemical cleanups, ensuring its longevity and reliability.

3000DSC |

|

|---|---|

| Alfreds Futterkiste | Maria Anders |

| Material | Stainless Steel 316L with electropolished process |

| Aseptic Doser Body Dimension | 945mm (L) X 340 mm (W) X 1544 mm (H) |

| Aseptic Doser Dosing Head | Standard 128 mm (OD) X 300 mm (H) |

| Aseptic Doser Weight | 45 kg |

| Head Pressure | 0.5psi |

| Volume Continuous dose | 461g |

| Dosing Accuracy | ±2% |

| Max. Line Speed | 800 CPM |

| Breaking Capacity | 4500 A Icn at 230 V AC 50/60 Hz conforming to IEC 60898-1

4500 A Icn at 400 V AC 50/60 Hz conforming to IEC 60898-1 |

Cryogenic Specialty Manufacturing Sdn.,Bhd

No 10, Jalan PPU 3A, 47150 Puchong,

Selangor, Malaysia

Tel: +603 8051 0982

Email: [email protected]